How-To Choose The Correct Check Valve

This short check valve video shows the different types of check valves and how to choose a check valve for your unit.

How to Choose the Correct Check Valve

- To find out the MPT size of the outlet threads you will need to measure the outside diameter (“O.D.”) of the threads going into the tank. The “MPT” size will always measure ¼” under the actual O.D. measurement of the threads. Hence, if the O.D. of the threads is 1”, you will need a ¾”MPT check valve, if the O.D. is ¾” you will need a ½”MPT check valve, etc. (pictured below is a ½”MPT check valve).

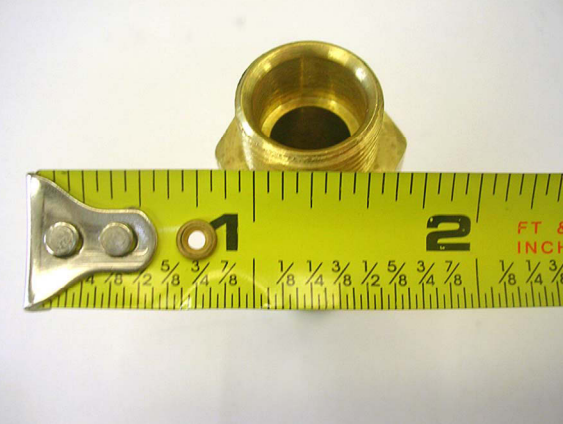

- When choosing a Flare-style Check Valve, measure the O.D. of the male flare threads. If it measures ¾”, then you will need a ½”MPT Flare Check Valve. The MPT size will always measure ¼” under the O.D. (outside diameter) of the male flared thread (pictured below).

- When measuring male Compression threads, measure the inside diameter (“I.D.”) of compression fitting. If the I.D. measures ½”, then you need a ½” Compression Check Valve (seen in the below photo). This measurement should also coincide with the outside diameter (O.D.) of the discharge transfer tube.

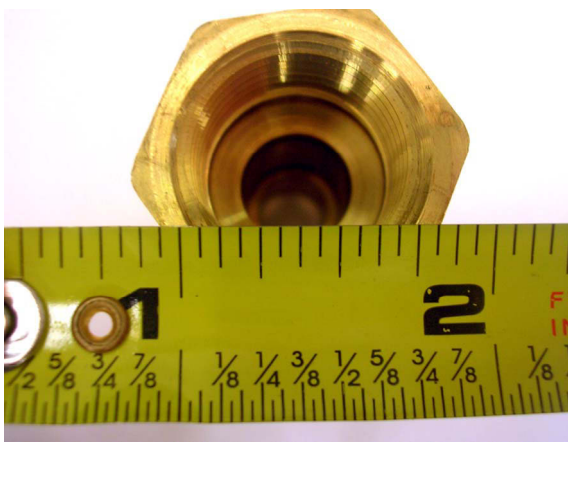

- When measuring a Female Pipe-style Check Valve (FPT), measure the inside diameter (I.D.) of the thread, like you would a Compression-style check valve. If the I.D. of the thread measures ¾”, then you need a ½”FPT Check Valve (pictured below). The FPT size will always measure ¼” under the I.D. measurement.