Air Compressor Repair: DIY or Hire a Professional?

Air compressors are essential equipment for auto repair shops, carpenters, roofers, painters, and anyone who uses pneumatic tools. Compressors can be costly investments, and it can be a major inconvenience when they break down. So should you go DIY or hire a professional for air compressor repair? Explore the factors to consider when making this decision, including identifying air compressor issues, looking at the availability of parts, and weighing the complexity of the problem.

Identifying Air Compressor Issues

One of the first steps in determining whether to fix an air compressor yourself or hire a professional is identifying the issue at hand. Some common air compressor problems include overheating, leaks, pressure problems, noise, and electrical malfunctions.

If you have experience with air compressors or a strong background in mechanics or electronics, you might be able to diagnose and fix these issues yourself. In contrast, if you lack the knowledge, it may be best to bring in a professional who knows their way around an air compressor.

Considering Part Availability

When deciding between DIY and professional repair, you’ll have to account for the availability of replacement parts. For some older and more obscure brands and models, you may find it challenging to find specific components necessary to fix your air compressor. In such cases, hiring a professional could save you time and eliminate the trouble of tracking down and ordering rare parts.

On the other hand, suppliers like Master Tool Repair carry a large selection of brand-name-compatible components, including Husky air compressor parts, among other well-known brands. If you know where to look, you could spend less this way.

Weighing the Problem’s Complexity

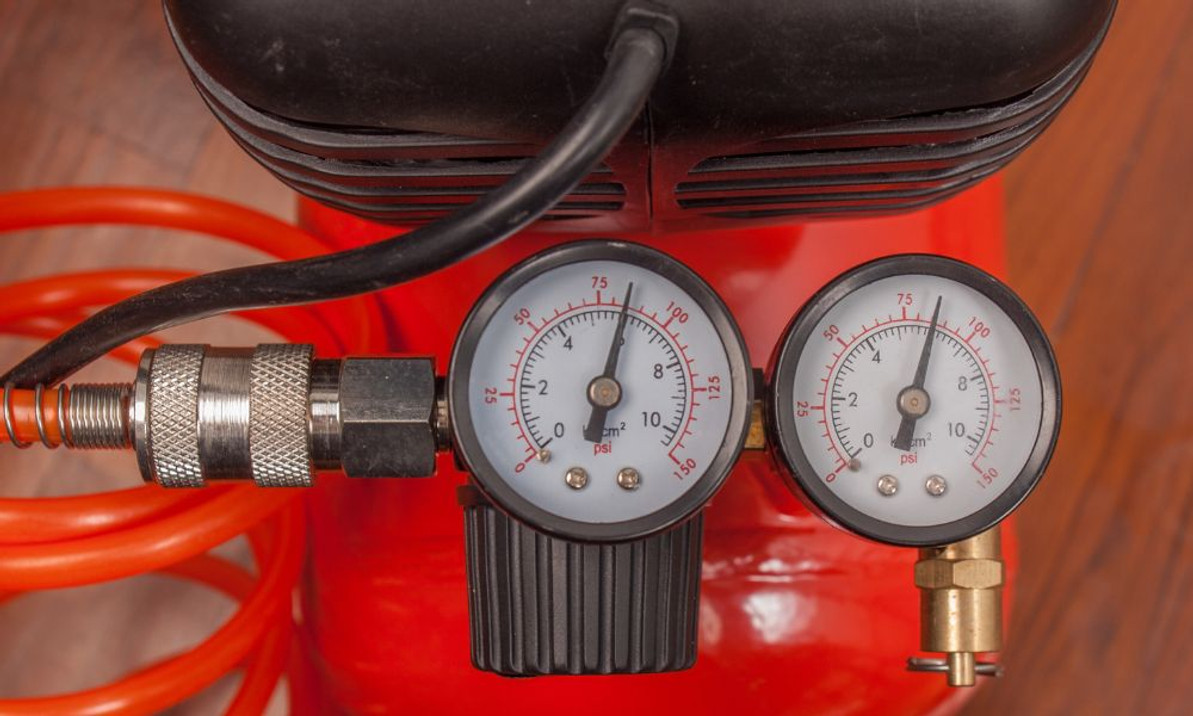

Some air compressor issues are relatively simple to fix, requiring little-to-no expertise, such as replacing an air pressure gauge, drain cock, air filter or regulator valve. In contrast, problems involving multiple internal compressor parts like valves, gaskets, pressure switches, piston rods, or crankshaft repairs may be best to leave to professionals. This is especially true with electrical issues that warrant electric motor or pressure switch repairs (or replacements). Before committing to a DIY repair, consider whether you have the necessary skills and tools to tackle the problem.

Pros and Cons of DIY Air Compressor Repair

Consider the following when determining whether to fix your broken air compressor yourself or hire a professional. These are the pros and cons of DIYing the job.

Pros:

- Saving money (the only cost is the parts and your own time)

- Reducing downtime (no waiting to pick up your machine from a shop)

- Extending the life of the equipment

Cons:

- Possibly voiding the warranty

- Making operation dangerous due to improper installation

The decision of whether to fix your air compressor yourself or take it to a professional ultimately depends on your specific situation. DIY repair can save money and reduce downtime if you know what you’re doing. Fortunately, Master Tool Repair provides helpful videos and schematics that can serve as a guide to repairs.

You can do most air compressor repairs easily and inexpensively without hiring a professional, so consider trying your hand at a small repair first. If you find yourself overwhelmed or requiring specialized parts, don't hesitate to contact Master Tool Repair for support.

Recent Posts

-

Air Compressor Pressure Switches: Beyond the Basics of Adjustment

The Brain of the Beast: Understanding Your Pressure Switch The pressure switch is the unsung hero of …Dec 10, 2025 -

The Breath of the Pump: Why Your Air Compressor Needs a Healthy Crankcase Breather/Vent

Your air compressor is a powerhouse, a workhorse essential to your operation. We all know the import …Dec 4, 2025 -

The Quiet Killer: How a Clogged Air Compressor Filter Destroys Your Pump

A well-maintained air compressor is the lifeblood of your workshop or job site. It runs reliably, re …Nov 19, 2025