Is Your Air Compressor Acting Up? Understanding Short Cycling and Constant Running

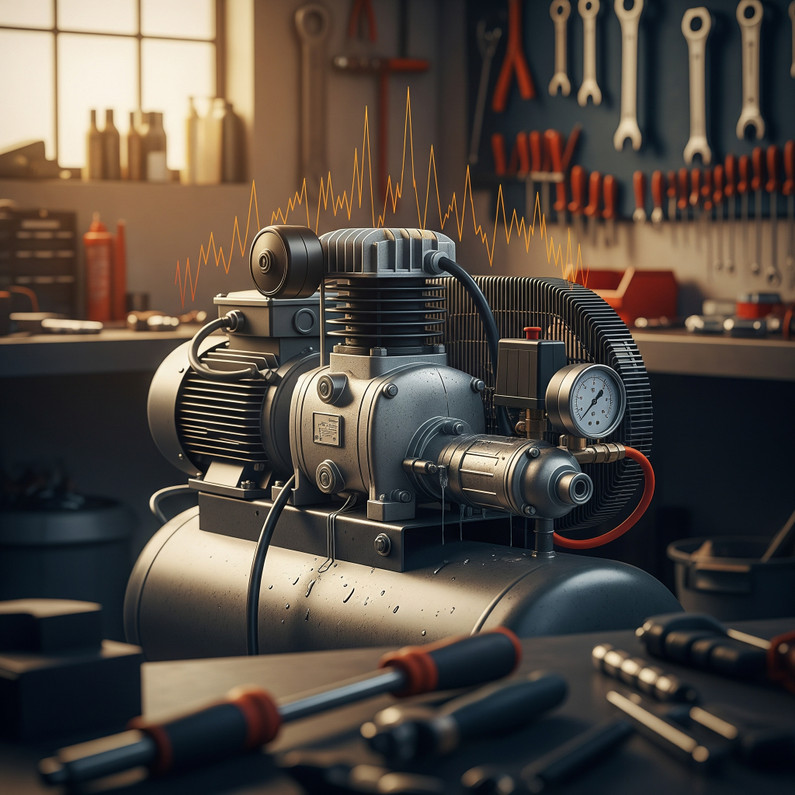

Air compressors are essential tools, but when they start acting erratically – either short cycling (turning on and off frequently) or running continuously – it can be incredibly frustrating and costly. This improper pressure regulation not only hinders your work but can also indicate underlying issues that need immediate attention.

Why Your Compressor Might Be Short Cycling

Short cycling occurs when your air compressor turns on and off too frequently. This can lead to increased wear and tear on components, higher energy consumption, and inconsistent air supply. Common culprits include:

- Air Leaks: Even small leaks in the air lines, fittings, or tank can cause the pressure to drop quickly, prompting the compressor to kick on more often to maintain pressure.

- Faulty Pressure Switch: The pressure switch is responsible for monitoring the tank's air pressure and signaling the compressor to start or stop. If it's malfunctioning, it might misread the pressure, leading to frequent cycling.

- Leaking Check Valve: Located between the compressor pump and the air tank, the check valve prevents compressed air from flowing back into the pump. A faulty or dirty check valve can allow air to leak back, causing the pressure to drop and the compressor to short cycle.

- Undersized Air Tank: If your air tank is too small for your air demand, the pressure will drop rapidly during use, causing the compressor to cycle on and off more often than it should.

- Dirty Air Filter: A clogged air filter restricts airflow into the compressor, making it work harder and potentially leading to overheating and short cycling.

What Makes a Compressor Run Constantly?

Conversely, an air compressor that runs continuously without shutting off is also a cause for concern. This often points to a significant loss of air or a control system failure. Here are some reasons:

- Significant Air Leaks: Large leaks in the system, possibly from damaged hoses, fittings, or tank, mean the compressor is constantly trying to compensate for the lost pressure.

- Continuous Air Demand: If the air usage by your tools or equipment exceeds the compressor's output, it will run continuously to try and keep up with the demand. Make sure to confirm your compressor’s “duty cycle” in the specifications that are listed in the owner’s manual. It could be that the air tank isn’t large enough (or the compressor’s output) for the application.

- Stuck or Faulty Unloader Valve: The unloader valve releases air pressure from the compressor head when it reaches its cut-out pressure, allowing the motor to start without pressure. If it's stuck closed, the compressor may struggle to reach the cut-out pressure and keep running.

- Malfunctioning Pressure Switch: Similar to short cycling, a faulty pressure switch might fail to signal the compressor to turn off once the desired pressure is reached, causing it to run continuously.

- Worn Piston Rings or Valves: Internal wear within the compressor pump itself, such as worn piston rings or damaged valves, can reduce its efficiency, preventing it from building and holding pressure adequately, thus leading to continuous operation.

Core Components Involved in Pressure Regulation

Understanding the key components that regulate your air compressor's pressure is crucial for effective troubleshooting:

- Pressure Switch: This is the "brain" of your compressor's on/off cycle. It senses the pressure in the tank and activates or deactivates the motor at preset cut-in and cut-out pressures.

- Check Valve: This one-way valve ensures that once air is compressed into the tank, it stays there, preventing backflow to the pump. A properly functioning check valve is vital for maintaining tank pressure.

- Pressure Regulator: While not directly involved in the compressor's run cycle, the pressure regulator controls the outgoing air pressure to your tools. If set incorrectly, it can sometimes contribute to perceived pressure issues.

- Air Tank (Receiver Tank): The tank stores compressed air, acting as a buffer and allowing the compressor to run in cycles rather than continuously. Its size and integrity are critical for stable pressure.

Get Your Compressor Back on Track

Identifying the root cause of short cycling or continuous running is the first step toward a solution. Master Tool Repair specializes in replacement air compressor parts, offering a wide array of high-quality OEM or compatible components to help you get your system back to optimal performance.

Recent Posts

-

Fix Low Pressure and Slow Fill: A Practical Troubleshooting Guide

Is your air compressor taking forever to reach "cut-out" pressure? Low pressure and slow fill times …Feb 10, 2026 -

What’s That Hiss? Demystifying the Unloader Valve’s Role

If you own an air compressor, you’ve heard it: that sharp psshhh sound the moment the motor shuts of …Feb 3, 2026 -

Air Compressor Tank Safety: Understanding Ratings & Inspection

Air compressors are the workhorses of many workshops and garages. But beneath the power and utility …Jan 27, 2026