Signs Your Air Compressor Pressure Switch Is Failing

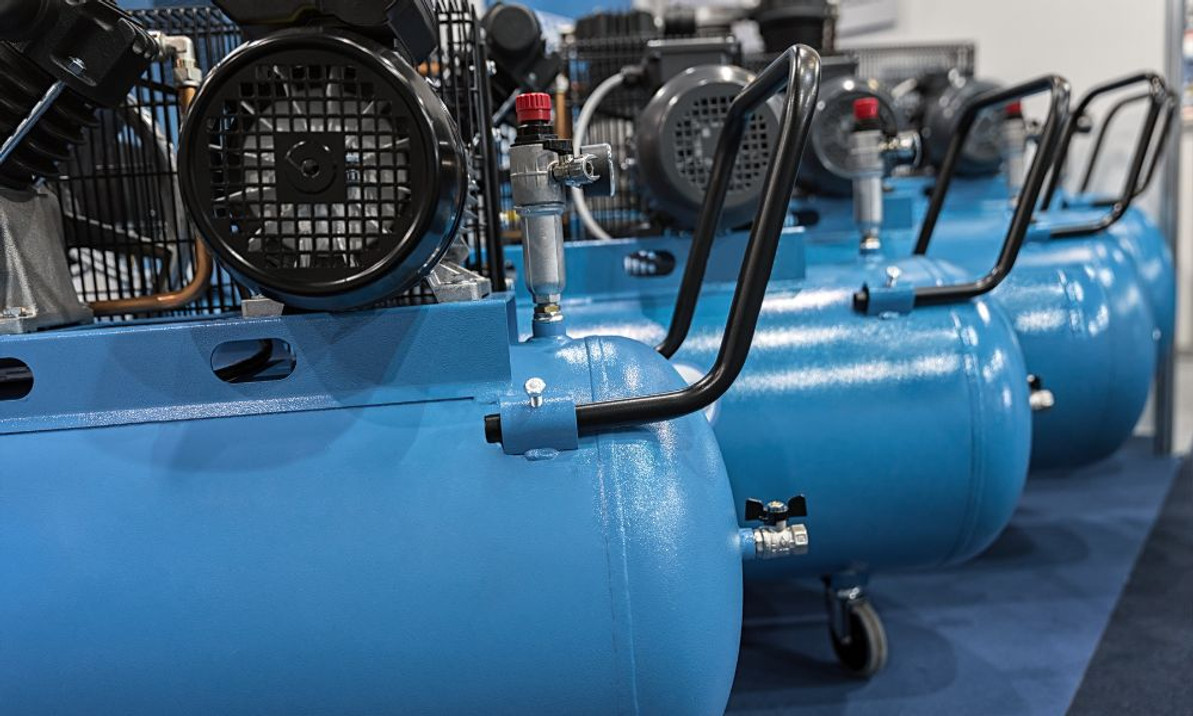

A portable air compressor is a versatile tool with a wide range of applications. However, like all machines, it may experience issues over time. One common problem area is the pressure switch. This crucial component helps control the amount of air pressure the compressor generates. Here are some key signs your air compressor pressure switch is failing.

The Compressor Doesn’t Cut Out or Turns Off Before Desired PSI

One of the most apparent signs of a failing pressure switch is when the air compressor doesn’t cut out when it should or turns off before reaching the desired PSI (pounds per square inch). The pressure switch should automatically stop the motor once the air tank reaches the set pressure limit. If the compressor continues to run despite achieving this limit or shuts down prematurely, that indicates a malfunctioning pressure switch.

The Compressor Doesn’t Cut In or Turn On

If your compressor doesn’t cut in when the pressure in the tank dips to the cut-in pressure setting or fails to turn on at all, even when there’s no electrical power issue, that could also point to a faulty pressure switch. The pressure switch is responsible for starting the motor when the air tank's pressure drops below a certain level. If the compressor doesn’t start despite a low pressure reading, the switch may be unable to correctly detect and respond to these changes.

Unusual Noise

If you hear unusual noises coming from your air compressor, don’t ignore them. Strange sounds often signal mechanical issues. A failing pressure switch might cause odd noises during operation. If you notice such sounds, it’s advisable to have a professional inspect your compressor.

Broken Knob or Switch

Physical damage to the pressure switch can also cause problems. A broken knob or switch is an obvious sign that you should replace the entire pressure switch unit. Regularly inspect your compressor to help detect such issues early, preventing further damage or complications.

Rust On Switch Components

Rust on the pressure switch is a bad sign. It not only indicates potential water damage but can also interfere with the switch's functionality. If you notice rust, consider replacing the switch to prevent more serious issues down the line.

Regularly inspecting and maintaining your portable air compressor can help you detect issues early and prolong the life of your equipment. If you notice any of the signs your air compressor pressure switch is failing, an air compressor pressure switch replacement may be in order. Addressing the issue promptly can help avoid further damage and ensure safe and efficient operation of your compressor.

Unloader/Bleeder Valve Leaks

Many pressure switches have either a straight or 90-degree unloader (or bleeder) valve on the bottom or on the side of the pressure switch, in which a small airline (usually ¼”) connects. A leak here usually doesn’t denote a faulty pressure switch but instead a faulty unloader valve or in-tank check valve.

If air leaks out of the unloader/bleeder valve while the unit is running, the valve is probably defective. If air leaks out of the valve after the unit shuts off, this is a sign of a faulty in-tank check valve. In this case, clean or replace the check valve.

Recent Posts

-

How to Properly Install a Pulley with a Bushing on Your Air Compressor Motor

Installing a motor or engine pulley may seem simple, but getting it right—especially when it i …Apr 24, 2025 -

Keep Your Air Compressor Steady – Don’t Skip This Simple Upgrade

No More Sliding, Shaking, or Skipping Around If you've ever had your air compressor "walk" acro …Apr 17, 2025 -

The Must-Have 16-Piece Air Tool Accessory Kit for Every Air Compressor Owner

Whether you're a seasoned DIYer, a weekend car warrior, or just someone who owns an air compres …Apr 9, 2025