What’s That Hiss? Demystifying the Unloader Valve’s Role

If you own an air compressor, you’ve heard it: that sharp psshhh sound the moment the motor shuts off. To the untrained ear, it sounds like a problematic leak. To a pro, it’s the sound of a healthy machine.

That sound is created by the unloader (or bleeder) valve. While it’s one of the smaller components on your compressor, it plays a massive role in ensuring your machine actually starts up the next time you need it.

What is an Unloader Valve?

The unloader valve’s primary job is to "unload" the trapped air pressure inside the discharge line (the pipe between the pump and the tank) once the compressor reaches its "cut-out" pressure and stops. It’s essentially a schrader valve, which is a spring-loaded valve that expels air in a pressurized system once the pressure switch turns off.

Why is it Necessary?

Electric motors and gas engines struggle to start under a heavy load. If the discharge line remains full of high-pressure air, the piston has to push against that pressure the very second it tries to move. This creates massive "head pressure."

Without the unloader valve, your motor would hum, overheat, or trip a breaker because it simply isn't strong enough to overcome that initial resistance. By venting that small amount of trapped air, the unloader valve allows the motor to spin up to full speed freely before it has to start pumping against tank pressure again.

Where is it Located?

Depending on your model, the unloader valve is usually found in one of two places:

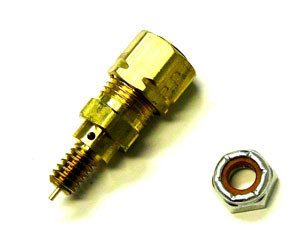

- On the Pressure Switch: Most small to mid-sized compressors have a tiny valve mounted to the side of the pressure switch with a small copper or plastic line running to it. Some pressure switch manufacturers have the unloader valve on the bottom of the switch, where the cast manifold is. Others have it located on the side of the pressure switch. The connection to the unloader tube can either be a compression fitting or a “quick-connect” fitting that doesn’t require a compression nut and sleeve.

- On the Check Valve or Pilot Valve: On larger or gas-powered units, it may be integrated into the check valve or a separate pilot valve assembly.

Signs of a Failing Unloader Valve

If your unloader valve is acting up, you’ll notice one of two symptoms:

- The "Continuous Hiss": If the compressor shuts off and the valve hisses indefinitely until the tank is empty, it’s actually usually a sign of a faulty tank check valve, not the unloader itself. The unloader is just doing its job venting air that the check valve is failing to hold back.

- No Hiss at All: If you don't hear that puff of air when the motor stops, the discharge line is staying pressurized. You’ll likely hear your motor "stall" or "grunt" when it tries to restart.

Need a replacement? At Master Tool Repair, we carry unloader valves and pressure switches for all major brands, including Craftsman, DeVilbiss, Porter-Cable, and more.

Recent Posts

-

Just Got a New Air Compressor Pump? Master the Air Compressor Break-In Process!

Congratulations! You’ve just upgraded your setup with a high-quality replacement pump. Whether you’r …Feb 17, 2026 -

Fix Low Pressure and Slow Fill: A Practical Troubleshooting Guide

Is your air compressor taking forever to reach "cut-out" pressure? Low pressure and slow fill times …Feb 10, 2026 -

What’s That Hiss? Demystifying the Unloader Valve’s Role

If you own an air compressor, you’ve heard it: that sharp psshhh sound the moment the motor shuts of …Feb 3, 2026