The Hidden World of Gaskets & O-Rings: Why Small Seals Matter Big

At Master Tool Repair, we understand that every part of your air compressor, no matter how small, plays a crucial role in its overall performance and longevity. While the big components often get all the attention, there’s a hidden world of unsung heroes working tirelessly behind the scenes: gaskets and O-rings. These small seals might seem insignificant, but their impact on your air compressor’s efficiency and lifespan is anything but.

What Are Gaskets & O-Rings?

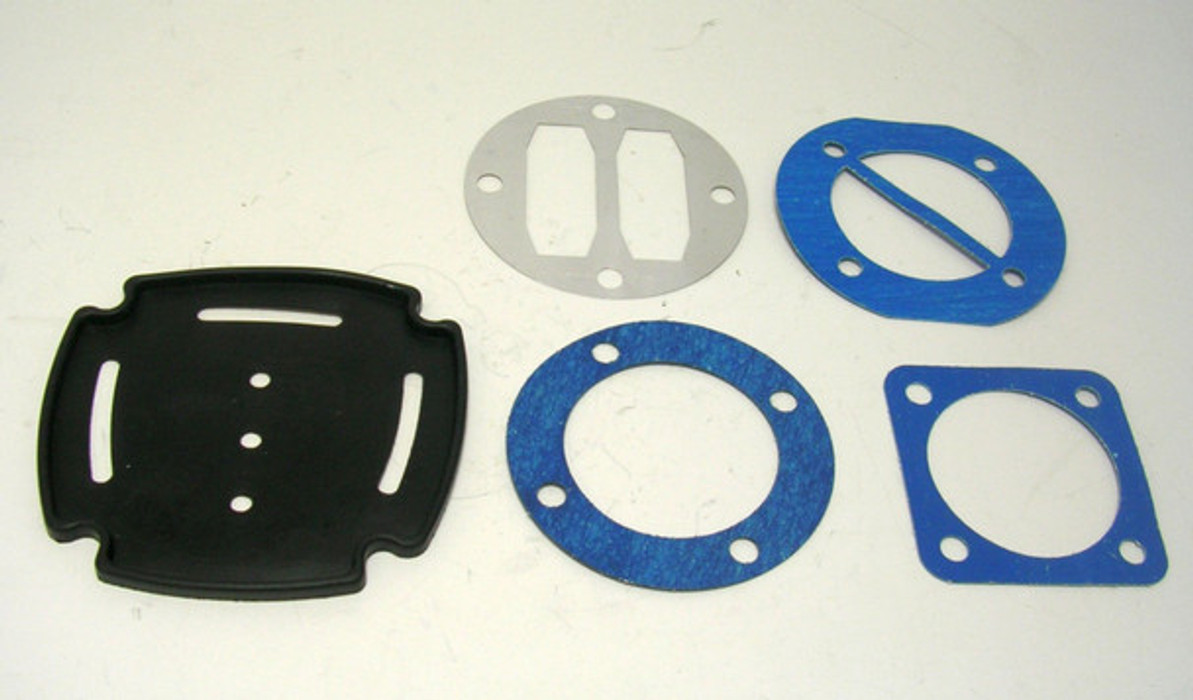

Simply put, gaskets and O-rings are mechanical seals that prevent leaks and maintain pressure within your air compressor system.

- Gaskets: Typically flat, these are used between two stationary parts to create a static seal. They come in various shapes and materials (e.g. cork, paper, graphite, etc.), designed to fill irregular gaps and prevent fluid or gas from escaping. Think of the head gasket on your compressor's pump, sealing the cylinder head to the cylinder block.

- O-Rings: These are donut-shaped rings, usually made of elastic material like rubber or silicon. They are designed to sit in a groove and be compressed between two or more parts, creating a tight seal. O-rings are highly versatile and are found in numerous applications within your air compressor, from valve assemblies to fittings.

Why Do These "Small Seals" Matter So Big?

The importance of well-functioning gaskets and O-rings cannot be overstated. Here's why they are critical to your air compressor's health:

- Preventing Leaks: This is their primary job. Even a small air leak can lead to significant pressure loss, forcing your compressor to work harder and longer to maintain the desired pressure. This not only wastes energy but also puts undue strain on the motor and pump.

- Maintaining Pressure & Efficiency: A sealed system ensures that the compressed air stays where it's supposed to be, allowing your compressor to operate at peak efficiency. When seals fail, your compressor's performance drops, and it takes more power to achieve less work.

- Protecting Components: Gaskets and O-rings prevent contaminants like dirt, dust, and moisture from entering critical components. These contaminants can cause premature wear and tear, leading to costly repairs or even complete system failure.

- Ensuring Safety: In some applications, air compressors handle high pressures. A faulty seal can lead to dangerous air bursts or component failures, posing a safety risk to operators.

- Extending Lifespan: By preventing leaks, maintaining efficiency, and protecting internal components, quality gaskets and O-rings directly contribute to the extended lifespan of your entire air compressor. They help minimize wear and tear, reducing the frequency of major repairs.

The Consequences of Neglecting Gaskets & O-Rings

Ignoring these vital components can lead to a cascade of problems:

- Increased Energy Bills: Leaks mean your compressor runs more, consuming more electricity.

- Reduced Performance: Lower air pressure and flow directly impact the effectiveness of your tools and operations.

- Frequent Breakdowns: Worn seals can lead to overheating, component failure, and unexpected downtime.

- Costly Repairs: Addressing the root cause of a leak or a component damaged by contamination is often more expensive than simply replacing a worn gasket or O-ring.

When to Inspect and Replace

Regular inspection is key. Look for:

- Visible Cracks or Deterioration: Seals can dry out, crack, or become brittle over time.

- Signs of Leaks: Hissing sounds or a noticeable pressure drop when the compressor is idle are clear indicators.

- Oil or Fluid Residue: Around sealed areas, this can point to a compromised seal.

It's generally recommended to replace gaskets and O-rings during routine maintenance or whenever you're disassembling a component that relies on them. Their low cost pales in comparison to the potential savings in energy, repairs, and prolonged equipment life.

At Master Tool Repair, we specialize in providing high-quality replacement air compressor parts, including a comprehensive selection of gaskets and O-rings for all major brands and models. Don't let a small seal bring your operations to a grinding halt. Investing in quality replacement parts now can save you significant time, money, and headaches down the road.

Recent Posts

-

Just Got a New Air Compressor Pump? Master the Air Compressor Break-In Process!

Congratulations! You’ve just upgraded your setup with a high-quality replacement pump. Whether you’r …Feb 17, 2026 -

Fix Low Pressure and Slow Fill: A Practical Troubleshooting Guide

Is your air compressor taking forever to reach "cut-out" pressure? Low pressure and slow fill times …Feb 10, 2026 -

What’s That Hiss? Demystifying the Unloader Valve’s Role

If you own an air compressor, you’ve heard it: that sharp psshhh sound the moment the motor shuts of …Feb 3, 2026